|

Forever Furnace Manufacturing Co.,Ltd

|

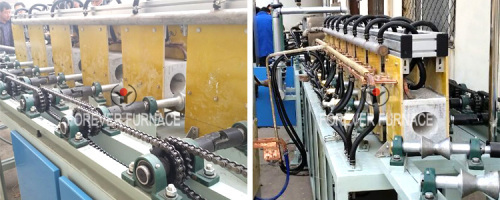

Crankshaft heat treatment equipment

| Price: | 500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Used for crankshaft heat treatment

Automatic feeding and discharging

Precious temperature monitoring and control

Advantages of Crankshaft Heat Treatment

Induction heating systems provide a fast, efficient and economical method of heating any electrically conductive material to a precise temperature. The equipment utilizes clean, readily available electric power to heat the entire surface of the work piece or selected specific areas. Heat depth can be limited to just the surface or can include the entire cross section. Temperatures are accurately controlled to meet the specific requirements of the application. Induction heat treating is equally efficient for job shop or high production operations. Since induction heating is clean and radiated heat is minimized, the process heating system can be installed directly in your production line or general work area. The equipment is compatible with existing in-plant material handling systems, and can be automated to meet specific production requirements. Typical advantages are:

Increased Production

· Fast localized heating reduces the processing time to seconds. Reduced heat and quench times.

· Compared with carburizing, induction hardening eliminates copper masking, packing, straightening and extra machining operations.

· Compact machines can be located close to related operations to avoid handling and reduce part inventories.

· Set-up changes for different parts are quick and easy.

· Machines either pace the operator, or are completely automated.

Lower Costs

· Scrap is reduced or eliminated by the use of precise controls.

· Distortion is minimized.

· Use of costly alloy steels is reduced or eliminated.

· Carburizing costs are eliminated.

· Warm-up time is eliminated, since power is on only during the heating cycle.

· Need for skilled labor is eliminated.

· Man-hours are reduced with high production rates.

· Working conditions are improved.

· Maintenance costs are reduced.

· Less floor space is needed.

Improved Products

· Localized heating and hardening minimize distortion.

· Surface hardening retains original ductility of core.

· The hardened area is accurately controlled in respect to case depth, width, location and hardness

Contact person:Tom wang

what'sapp:+8613303078975